Release time:2018-04-17 16:43:18

|

Rolling Department is one of the main international technical departments of TSIC which had developed from the process room of TSIC Design Department with only five people in 1973 to an independent department with professional echelon of mature steelmaking, rolling and rolling equipment and 40 professional technicians who have middle or senior titles. After 44 years of inheritance and development, with the vicissitudes and rebirth of TSIC, the Rolling Department is firmly established in the competitive market with its unique technology and services.

The Rolling Department consists of 3 professional leaders, 12 technical experts, 22 technical backbone, more than 50% staff with senior technical titles and 40% with master's degree.

Rolling Department is dedicated to provide technical services from engineering diagnosis, consultation, scheme planning, design, supervision, project implementation to production and operation for customers at home and abroad.

|

|

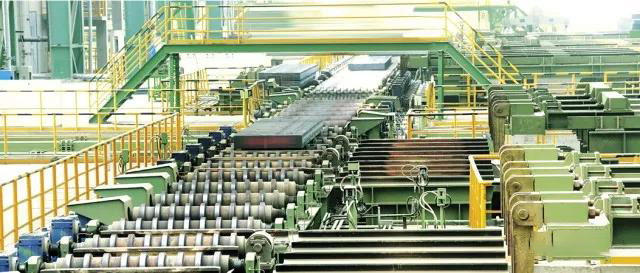

▲ 连续酸洗生产线

|

|

◢ Certificate

Class A in Metallurgical Industry Design, Class A in Construction Industry Design, Class A in Engineering Consulting, Comprehensive Qualifications of Engineering Supervision, State Qualifications for Contracting Projects to Foreign Countries, Class B in Engineering Cost Consulting.

|

|

◢ Specialty and Products

Ⅰ Steelmaking TSIC Steelmaking specialty is the pioneer of scientific and technological innovation in domestic steelmaking and continuous casting projects. Adhering to the concept of 'fine design', the Steelmaking specialty provides customers processes, equipment and engineering technology with all-round one-stop service covering liquid iron pretreatment, converter steelmaking, electric furnace steelmaking, slag treatment, out-of-furnace refining, continuous casting.

|

| ▲ 2×210t converter |

| The Steelmaking specialty provides scientific and economic technology allocation route and refining method according to Customized requirements of customers, Controlling process index precisely with low cost and coordinate the process configuration with product position. It also focuses on the in-depth study and wide application of the rational allocation of material flow, medium flow and energy flow and the utilization of energy-saving equipment and technology. |

| ▲ 1700板坯连铸机 |

|

At present, the steelmaking specialty has 130 mature 30-180 t series converter products, 48 30-100 t series electric furnace products, 126 continuous casting achievements such as square billet, round billet, rectangular billet, slab, thin slab.

Ⅱ Steel Rolling

TSIC Rolling specialty has formed its unique technical advantages in engineering design, consultation, general contracting and complete sets of equipment for wire stock, bar, section steel, slab band, reheating furnace, cold rolling and deep processing projects after years of practice.

|

| ▲ Bar Production Line |

| Especially in the design of technological renovation of old mills, Steel Rolling specialty grasps the advanced technology, and explores a lot of new ideas and methods of energy saving, low carbon, environmental protection and green from process flow to equipment selection. |

| ▲ Cold Rolled Annealed Coil |

|

The Steel Rolling specialty has abundant mature achievements in the fields of high-speed wire stock, bar, narrow strip, wide strip, section steel production line and cold rolling deep processing. Ⅲ Steel Rolling Equipment TSIC Steel Rolling specialty mainly undertakes the design of non-standard equipment for steelmaking, continuous casting, rolling, heating furnace and deep processing of steel rolling, hydraulic system, dry oil lubrication system, pneumatic system, as well as the design of machine repair specialty. |

| ▲ Slab Roller of Slab Caster |

|

The specialty of steel rolling equipment has rich experience and achievements in hot roll table, weighing roll table, steel loading machine, air-cooled roll table, heating furnace bottom equipment and non-standard equipment design of steel rolling finishing. Especially in the renovation design of non-standard equipment in old factories, we have prominent competitive advantages.

◢ Scientific Research Strength TSIC, as the backbone of China's metallurgical engineering technology field, persist in independent innovation as the driving force, and has a high-level, high-quality research team of about 100 people. Independently, we developed a series of core technologies and equipment which is international and domestic leading, and closely joined scientific research institutes and production enterprises to form a research and development mode of integration of production, learning, research and marketing. We have won more than 100 national or provincial awards for excellent engineering design, invention, scientific and technological progress, and excellent engineering quality management. |

| ▲ Heating Furnace |

| The steel rolling Department has made full use of its technical influence and achieved a lot of research and development achievement in the fields of steelmaking technology, rolling technology and non-standard equipment. There are 13 patents and 19 patents which are under review and ready to be declared. By actively promoting the transformation of scientific research achievements to core productivity, the annual contribution rate of output value can reach 10%. |

|

Key Research and Development Achievements of Steel Rolling Department

√ New Technology of Steel Slag Thermal Suffocation Treatment √ Deep Processing Technology of Steel Slag High Efficiency Magnetic Subgrade Material Powder Trinity √ Cold-solidified pellet technology for converter dry dust removal √ Bottom Blowing Technology of Converter and Baking Technology of Burning Beam-type Ferroalloy √ Full Process Covering Technology for Steel and Iron Ladle √ Double-connection Super-high Phosphorus Liquid Iron Steelmaking Technology for Electric Arc Furnace and Converter √ Energy-saving Burner Technology For Heating Furnace √ Intelligent Logistics Technology in Steel Rolling Workshop √ Sealed Conical Valve for Feeding √ Gasification Cooling Flue Water-cooled Feeding Gate with long-life √ Technology of Fiber Formation of BF Slag by Electric Furnace Tempering and the Production of Building Thermal Insulation Board |